Researchers at Fraunhofer Institutes have developed a framework using AI and optimization algorithms to help find optimal production settings. Bayesian optimization is used for efficient process improvement with limited data, often achieving optimal settings after about ten experiments. When only historical data exists, they train machine learning models followed by blackbox optimization, which is less efficient and accurate but avoids costly experiments. Current work is focusing on multi-objective optimization for sustainability and incorporating expert knowledge into the framework.

| Topic Fields | |

| Published | 2023 |

| Involved Institutes | |

| Project Type | ICNAP Research/Transfer Project |

| Responsibles |

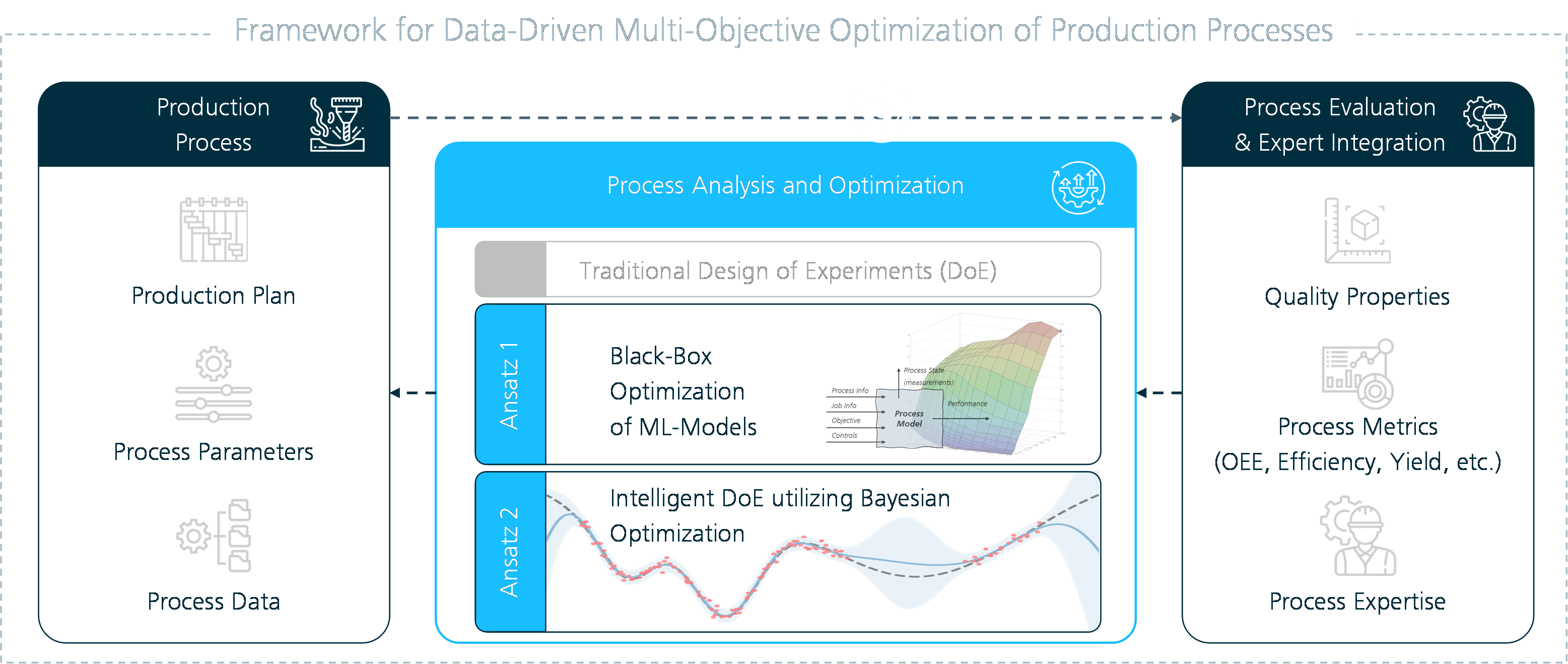

The identification of optimal production settings holds large potential for improving operational efficiency, reducing costs, increasing productivity, and enhancing product quality. A group of researchers from Fraunhofer IPT, IME and ILT developed a framework with which AI methods and optimization algorithms can assist production experts in optimal process design.

With limited data and the ability to perform new experiments, Bayesian optimization allows for sequential and highly efficient process improvements. We show that, depending on the complexity of the process, the optimal parameter set can be found after about ten experiments. If, however, only historical data is available, it is favorable to first train machine learning models and apply blackbox optimization algorithms afterwards. This can be less efficient and accurate but does not require conducting expensive experiments.

To also use the software for sustainability improvements of production processes, the team is currently working on multi-objective optimization and on better integration of expert knowledge.

Contact us to get in touch! With a membership, you’ll gain full access to all project information and updates.

© Fraunhofer 2026